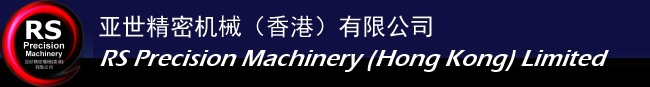

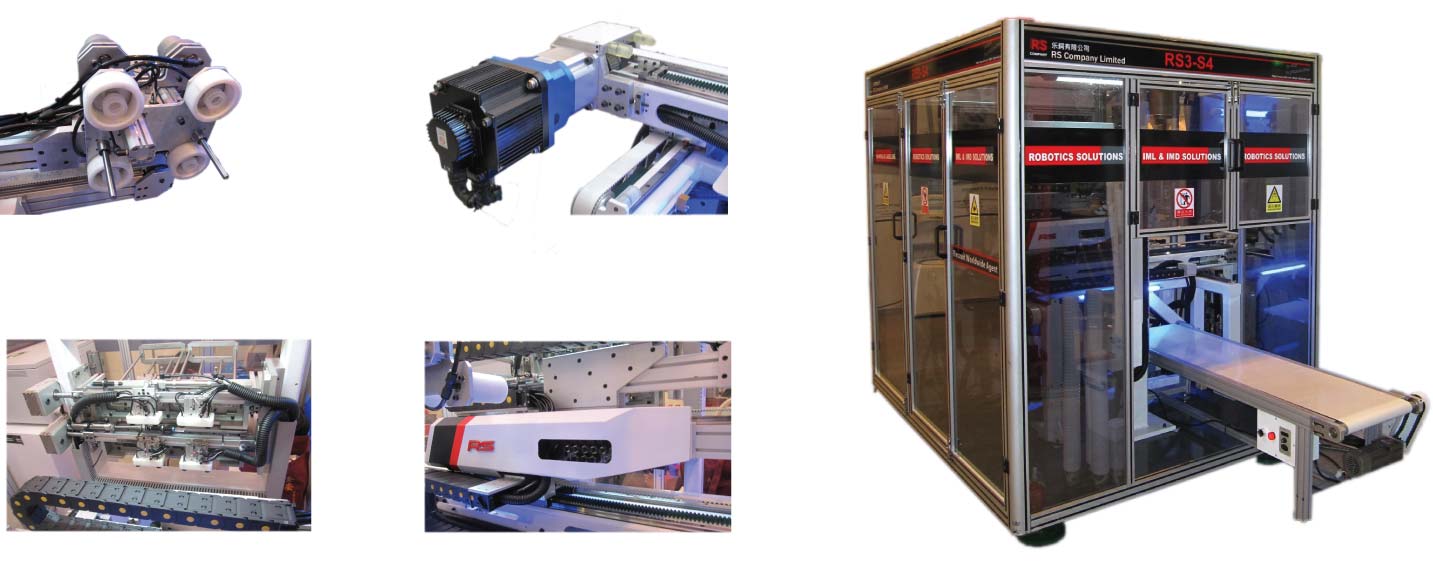

In-Mould Labeling System(IML) RS3 Series

In-Mould Labeling System (IML) robotics system is integrated and fully automatic, providing clients with IML devices more reliable and accurate. With extensive experience in IML production.

RS Precision Machinery (Hong Kong) Limited provides professional pre-sales and pro-sales services as well as one stop project development, including the production of precise high-speed labeling injection mold and fully automatic IML in-mould labeling robotics system with the required injection craftsmanship and technology.

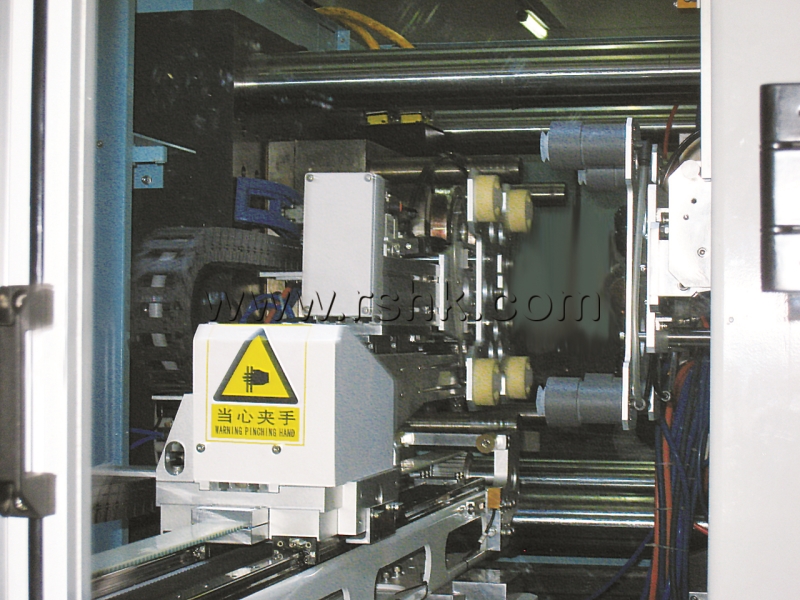

A wider scope of application with various functions and higher flexibility:

Outfitting or changing parts at all times to accommodate different production conditions and complement the manufacture of different IML/IMD products, for instance, airline cups, fast food boxes or bowels, ice-cream cartons, lids and appearance characteristics of such diverse products as cases of electronic products and auto decoration components.

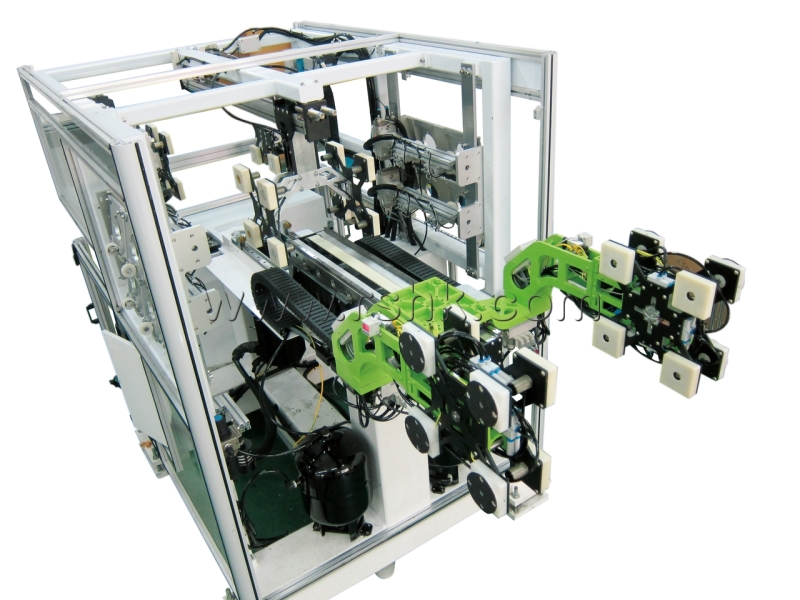

Install and adjust with greater speed and precision

The one-unit floor-standing composition integrated film collection and insert systems into one. Each system is connected strategically, positioned by digitalized logic and supplemented with steering control for parallel level increase. Adjustment is made easy and quick. Positioned with universal joint, the film insert system allows fine-tuning more accurate at your will.

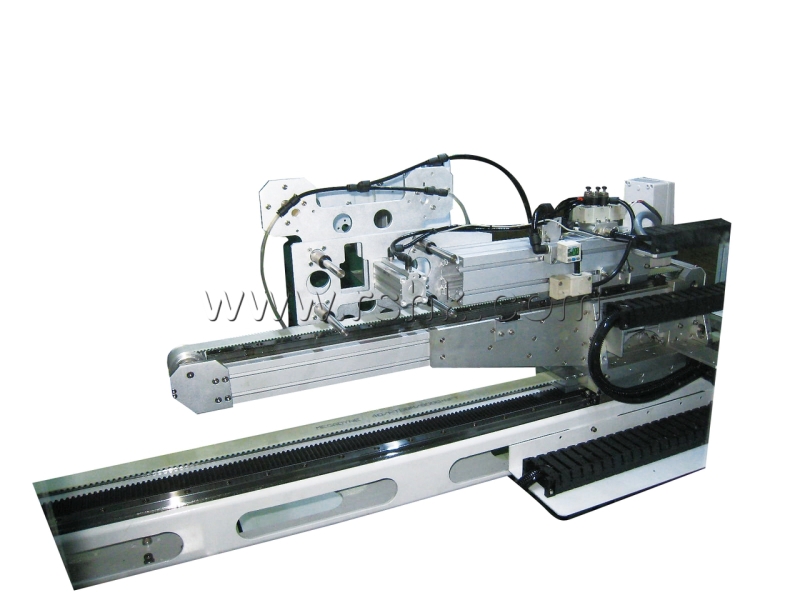

Application features

A single machine is compatible with injection machines ranging from 80 to 400 tons

A single machine can shite to produce one-side, three-side, five-side and round-wrap products as desired

A single machine can be equipped with different components to accommodate different mould cavities needs

A single machine can be equipped with fully automatic product collection and stacking system, products then dispatched via conveyance belt

Sufficient in coordinating with a variety of production scales and designs, considerably reduces investment amount and defected goods; relatively boosts efficiency and performance in production and brings advantages of flexibility ,storage and management. A machine specific system is customized to fulfill high-speed production requirements.

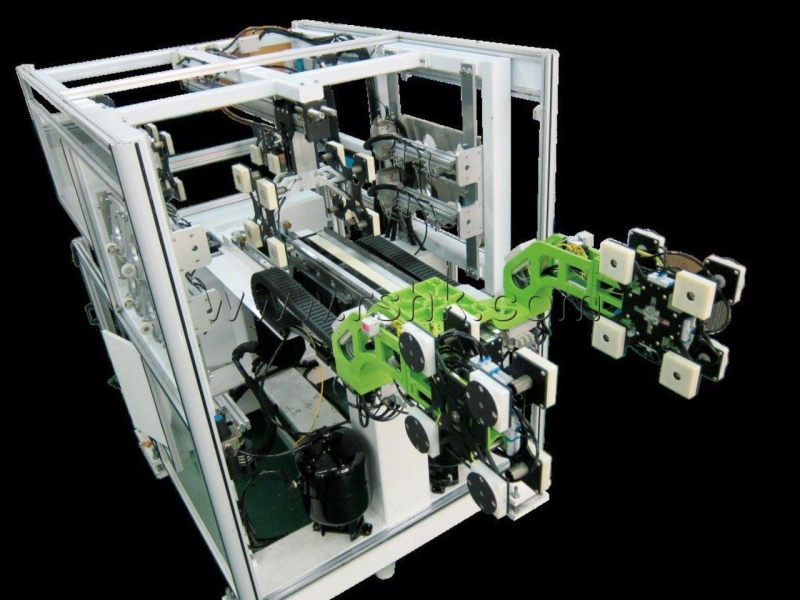

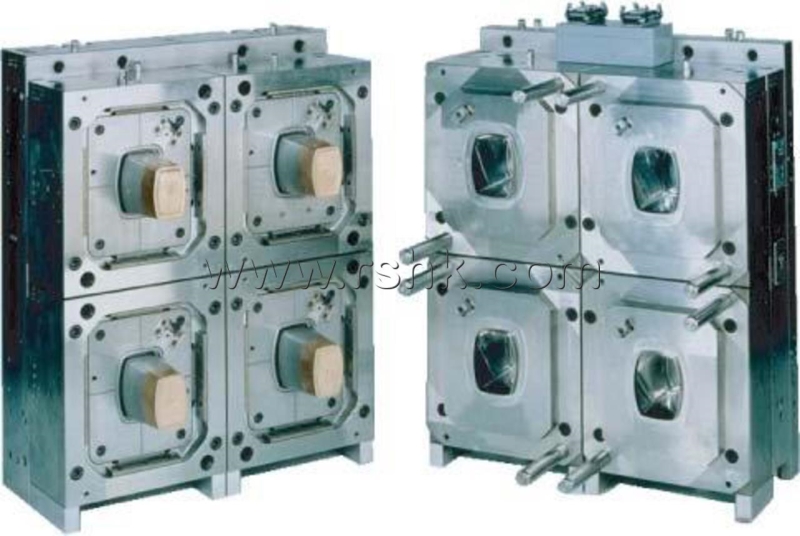

RS-V Series Stack Mould In-Mould Labeling System (IML)

A more dependable and durable system. The system utilizes only imported parts:

PLC controller, servo motor and driver from renowned Japanese brands. Pneumatic components are selected from SMC Japan; actuator parts, for instance, ball screws and roller guides are imported from Japan as well. The system ensures higher reliability and durability, tremendously cuts down time cost and repair expenditure.

The pictured shown as above is the RS-V-series.

Mould tooling and IML System can Customer made from:

* 1 cavity + 1 cavity design

* 2 cavities + 2 cavities design

* 4 cavities + 4 cavities design

* 8 cavities+ 8 cavities design

*Depends on product size.

Inquiries about the other lines of IML/IMD systems we provide are welcome.